Mining & Tunneling

Chemical solutions for underground construction

Our comprehensive portfolio includes solutions for:

Unexpected water ingress and poor ground conditions during mining and tunneling operations can cause significant problems for underground contractors. Pre-injection and post-injection technologies from Master Builders Solutions offer high-performing chemical and non-chemical products suitable for:

- Water and crack sealing, void-filling

- Strata stabilization, ground consolidation, structure repair

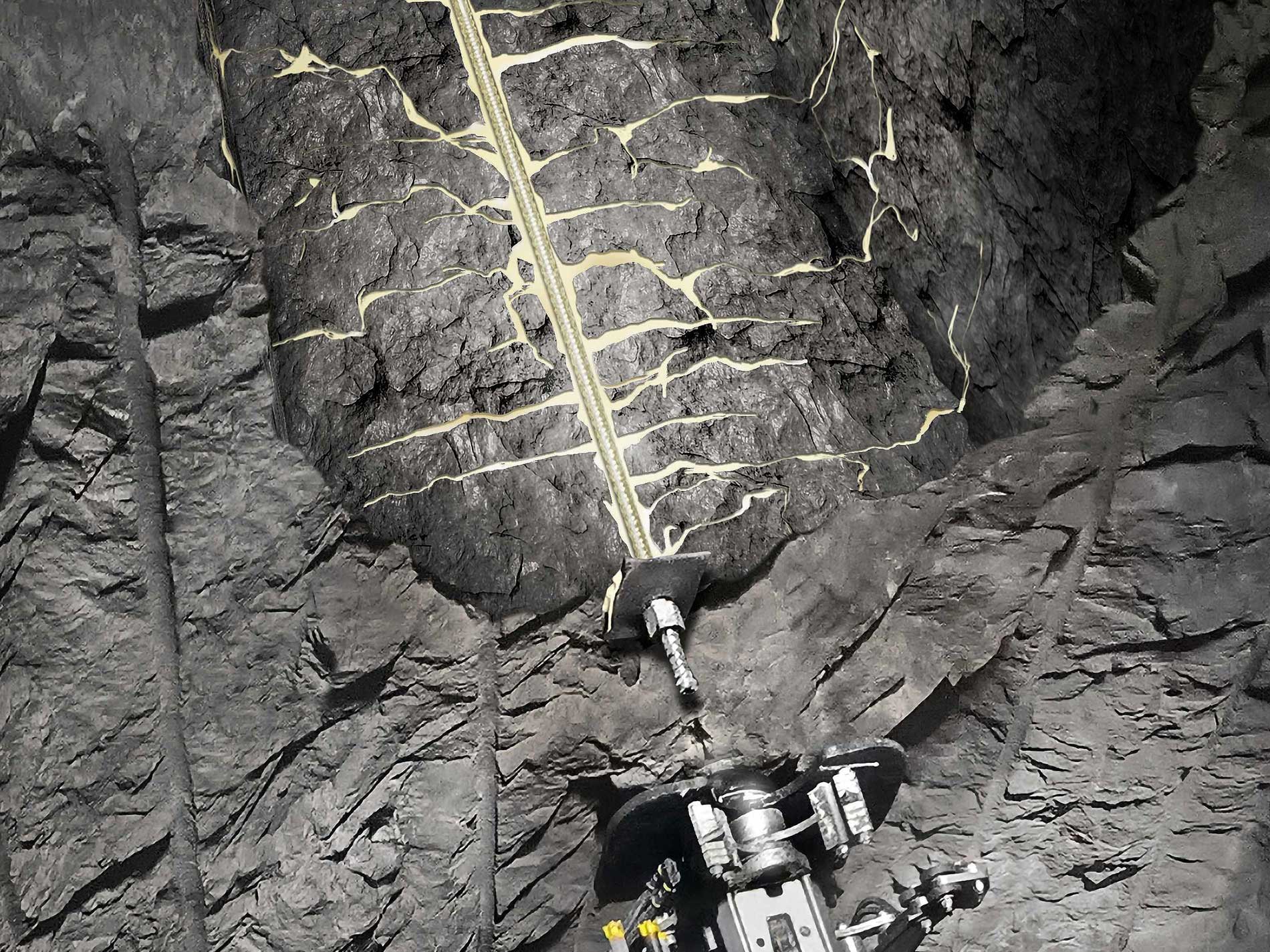

Master Builders Solutions offers a wide range of rock bolting solutions that facilitate safe ground stabilization while improving mine productivity. Developed for placement of cable and rock bolts in underground mines, our innovative solutions improve cycle times for both cable and rock bolt installation, while increasing worker safety and strata control.

Besides reactive resins from the MasterRoc RBA 38X range the portfolio includes also ready-to-use cementitious products and various admixtures for OPC based grouts to adjust the behavior in terms of shrinkage compensation, corrosion protection, pumping capacity, and bond improvement.

- MasterRoc RBA 380: compact thixotropic polyurea silicate injection resin, specifically designed for rock and cable bolt installations

- MasterRoc RBA 387: extremely fast reacting compact thixotropic polyurea silicate injection resin suited for self-drilling anchors, hollow bolts and automated installation

For more information,

click here

Mine stability after placement

Mine backfill technologies help to provide an optimum balance of high early strength and sustainable long term strength, ensuring dimensional stability after placement to meet or exceed design fill performance requirements. Our range of MasterRoc backfill admixtures can help customers challenge conventional physical limitations by:

- Improving backfill durability

- Controlling retardation, acceleration and rheology

- Modifying viscosity, reducing yield stress and pumping pressures.

State-of-the-art technologies for high quality, durable concrete tunnel segments

This high-range water reducing admixture is based on the new generation of polycarboxylate technology that incorporates state-of-the-art molecular engineering to provide fast wet-out of powder materials. Benefits to concrete production are:

- Rapid cement dispersion

- Superior early and ultimate strengths

- Increased productivity

Early and long-term strength in ground support

Achieve early and long-term concrete strength in ground support with Master Builders Solutions' comprehensive products that allow durable sprayed concrete structures to be constructed successfully and safely. These products are designed to:

- Meet your challenging site requirements

- Offer compatibility with local cements

- Provide fast set times

Improve operational efficiency in TBM excavation

Master Builders Solutions' comprehensive product portfolio for tunneling and tunnel boring machines improves operational efficiency in soft ground and hard rock TBM excavation. We help you meet your biggest challenges from the start of your project by offering:

- Laboratory resources for project specific testing

- Technical consulting for every stage of your project

- Global solutions

Our product range for TBM encompasses soil conditioners, anti-wear agents, tail sealants, main bearing greases, concrete admixtures for annulus grout applications and concrete segments, injection products as well as sprayable membranes.

Our new tail seal greases:

- MasterRoc TSG 870: new first fill tail grease for shielded tunnel boring machines that protects the brushes by preventing the penetration of water, soil and annulus grout. Additionally, it ensures the flexibility of the brushes, necessary to follow the movements of the tail shield.

-

MasterRoc TSG 800: tail sealant for shielded tunnel boring machines. It contributes to the formation of the essential tail seal preventing grout and other fluids from entering the tunnel area immediately to the rear of the TBM.

For more information on MasterRoc TSG 800, click here

Our new high-performance foaming agents have been specially formulated to improve the performance and control of the soil through the screw conveyor under the toughest conditions. Designed for silt to sandy soils, the highly stable foams are based on biodegradable raw materials:

- MasterRoc SLF 325: highly stable fine foam to hold the face pressure and maintain the rheology of the excavated ground longer than conventional foaming agents. For more information on MasterRoc SLF 325, click here

- MasterRoc SLF 419: similar performance to MasterRoc SLF 325. Ideal for use in cooler climates or environments. For more information on MasterRoc SLF 419, click here

- MasterRoc SLF 543: the special selected anti-clogging polymer effectively reduces the clogging and adhesion potential of clay containing soils on the cutterhead. Suitable for use in a wide range of temperatures.

Sprayable membrane for waterproofing concrete structures

Spray-applied membrane can be applied between layers of sprayed or cast-in-place concrete, or applied as a stand-alone membrane, exhibiting high bond strength to the substrates on both sides of the membrane.

- High bond strength to substrates

- Good elasticity

For more information,

click here

Please select your region

North America

Europe

Australia & Pacific